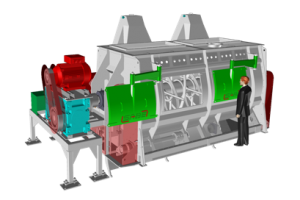

Ribbon mixer

Ribbon mixers are used to consistently mix flours with a 5 or 6 % inclusion of oil and grease

SABE ribbon mixer general specifications:

- Working capacity: 6000 to 12000 litres

- Minimum capacity: About 30% of the working capacity

- Mix density: 0.3 to 1.2 T/m3

- Number of mixes per hour: 12 max.

- Emptying time: 30 seconds

- Mixing tools: Double ribbon rotor

Discover its advantages:

- Low electricity consumption, for example: 45kW to 75kW power for an 8,000 litre machine depending on the formulae and liquid content levels

- Minimised retention and contamination thanks to a new mixer body shape and its integral wide-angle emptying hatch

- Increased seal tightness for very finely graded products. Leak tightness provided by adjustable glands and compressed air pressurisation under 0.5 to 1 bar

- Excellent mix consistency CV <5% (for example: gross CV on latest installed mixer 1.6%)

- 2 large accessible side doors for easier cleaning

- Easy access for maintenance through good mechanical access ergonomics

- Liquid injector plates built into the body on both sides

- Rotor specially designed for sticky products with a reverse possibility for thread and shaft self-cleaning. Free rings guaranteeing shaft self-cleaning

- Gentle mixing without heating the product and without wear on the mixing components

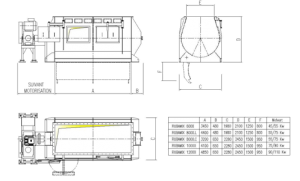

Mixer space occupation:

The measurements are given as an indication

Download the SABE ribbon mixer product sheet here.