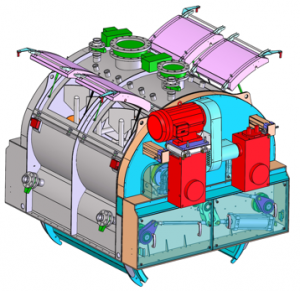

Twin Shaft mixer

Why use a SABE Twin Shaft mixer?

- Very short mixing time in the order of 10 to 60 seconds depending on the type of component.

- No segregation during the mixing phase.

- Ideal for mixes containing products with different gradings and densities.

- Very low coefficients of variation, <5%.

- Liquid injection in the fluidisation zone.

- Particle fluidisation in the mixing zone. Ideal for fragile products.

- Low peripheral blade speed.

- High hourly production using a reduced size machine.

- No segregation.

- Very low installed power per tonne.

- No segregation during emptying due to the very short emptying time: < 10 seconds.

- No product heating or shearing.

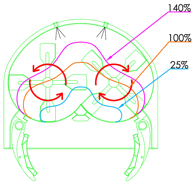

- High variation of batch sizes on the same machine, 25% to 140%.

The advantages of the SABE Biromix:

- Large sized 60° emptying door to minimise retention and provide very fast emptying (reduced cycle times).

- Increased leak tightness for very finely graded products. Leak tightness using a gland and optional air blowing.

- Large sized plumber block and offset seal tightness system.

- Over-sized rotor shaft.

- Rounded tank design to minimise product retention inside it.

- Easy to clean

The mixer options:

- Steel or stainless steel construction with different.

- Internal and external finishes.

- Construction in a vacuum. Value: -200mbar.

- Coating.

- Atex (construction and safety).

Examples of applications:

- Animal Feed

- Pet food

- Human food

- Chemicals

- Minerals

- Pharmaceutical

Filling rate from 25% to 140%

Download the SABE Twin Shaft mixer product sheet here.